Thanks to 3D printing, ‘They know who I am — I’m grandpa’

In an instant — the grasp on the hand brakes, the squealing tires, the realization of what was to come, the unavoidable collision between motorcycle and passenger side of a pickup truck — everything changed for John Roby.

The details are fuzzy and traumatizing for John, whose memory mostly is built from the accident report and reconstruction — and it’s not a moment to which he wants to return. That’s because he was seriously injured in the crash and unconscious in the aftermath.

From the collision until he awoke in a Mayo Clinic hospital bed, there is nothing.

“I can’t tell you all the details of how I ended up here because I was unconscious when I was brought here,” John says of the helicopter flight from near Mankato, Minnesota, to Mayo Clinic Hospital — Rochester, Saint Marys Campus. “If it wasn’t for helicopters and doctors, I would not be here talking to you today.”

Although he does not know the how, he is keenly aware of the why he was taken to Mayo Clinic. And he is grateful. He was, he says now, unrecognizable — “a broken mess of bones.”

And, John says, thanks to Mayo Clinic surgeons and doctors, technologists, nurses and everyone else involved in his care, everything has changed again. He has been put back together.

The collision

John was driving a motorcycle along Route 169 near Mankato when he collided with another vehicle that had turned into his path. Even wearing a helmet, John had life-threatening injuries that required immediate care.

He was transported by Mayo One, a helicopter air ambulance, to Mayo Clinic in Rochester.

John had extensive facial trauma and facial fractures involving his upper, middle and lower face, says Dr. Basel Sharaf, a plastic and reconstructive surgeon at Mayo Clinic. The meticulous planning needed to help John led Dr. Sharaf to Mayo Clinic’s 3D Anatomic Modeling Laboratory.

Reconstruction road map

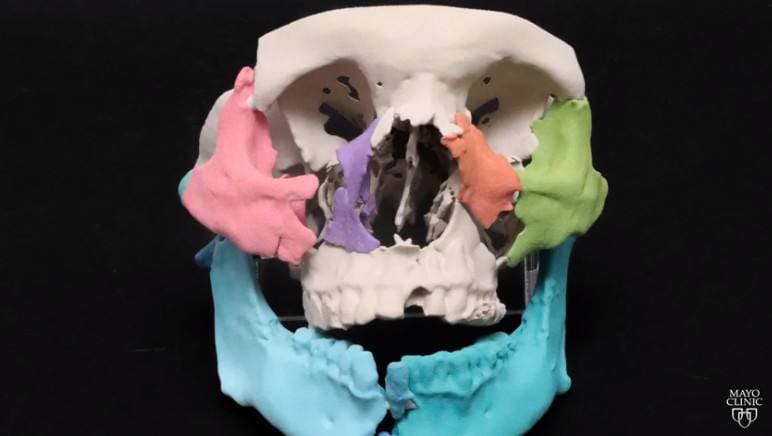

Dr. Jonathan Morris, director of the 3D Anatomic Modeling Lab, says CT scans of the head and neck allowed the engineering team to create a series of life-size, patient-specific models of John’s facial bones and the pathologic fractures. The Anatomic Modeling Unit used a computer-aided design program to replicate his face and skull in 3D, which was used to 3D-print the replicas.

First, Dr. Morris and the Anatomic Modeling Unit used his CT scan to recreate his face with each independent fracture fragment as a separate color. This then allowed Drs. Morris and Sharaf to begin to move the fragments to where they should be situated based on normal facial measurements and mirror imaging of his normal side. The surgical team used recent photographs of the patient to guide them in this process, as well.

Second, the team 3D-printed multiple patient-specific models, including the skull with all of the fractured fragments and a second version of the now perfected and reassembled skull based on jigsaw puzzle reconstruction with Dr. Sharaf’s guidance.

Traditionally, the plates used to fix the fractured bones are bent and adjusted in the operating room after the surgeon puts all the pieces together. Using virtual planning and 3D printing, Dr. Sharaf used the perfected 3D-printed models to preoperatively bend the needed surgical plates to be used in the reconstruction, saving significant time during the surgeries. In addition to saving time, the plates act as surgical guides to accurately build the facial bones back to normal.

“By collaborating between Engineering, Radiology and Plastic Surgery, we’re able to create a perfected skull, where all the parts that we previously had created are now in the right area and in the right location ― both for the form of his skull, so that he looks normal, but also so that it functions normal,” Dr. Morris says.

Third, after the reconstruction a final 3D-printed skull was created to show the reconstruction, including all the plates and bones in place.

John says seeing the models of his own anatomy is spooky.

The transformation

Before Mayo Clinic had on-site 3D printing, complex surgeries like John’s were performed in the operating room. While there was planning, it lacked the detail that 3D-printed models allow.

“When you have extensive facial trauma, usually without this intermediate layer of virtual planning and 3D printing, we have to achieve the final reconstruction in the operating room,” Dr. Sharaf says. “Oftentimes, there is quite a bit of facial swelling, and that sometimes can interfere with your ability ― even with experienced hands ― to achieve the best reconstructive outcome, especially when you are trying to rebuild the facial skeleton in three dimensions.

“Having the 3D-printed model and the virtual plan ahead of time and having these plates, which you see here on the reconstructed, 3D-printed model, … really helps in achieving the actual plan you had planned ahead of the surgery. So it’s just adding an extra layer of accuracy, I think, to the surgical reconstruction.”

John’s road to recovery is lengthy, with multiple surgeries across specialties to address the wide range of injuries. But the progress has given back to John and his family something that had been taken away back in that moment in June 2020.

“I recognize me,” he says. “And the most important thing is my girlfriend does and my grandkids recognize me. They know who I am — I’m grandpa.”

“My experience at Mayo Clinic has been rewarding. Every time I leave here, I leave better than when I got here,” says John.

____________________________________________

For the safety of its patients, staff and visitors, Mayo Clinic has strict masking policies in place. Anyone shown without a mask was either recorded prior to COVID-19 or recorded in a nonpatient care area where social distancing and other safety protocols were followed.

This story also appears on the Mayo Clinic News Network. You can find it there and share it with others